100% RENEWABLE ENERGY

The Olbia plant used 100% renewable energy supplied by the Romagna Energia consortium.

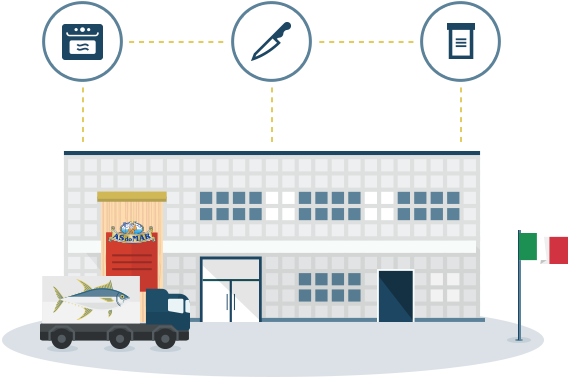

WE PROCESS OUR TUNA IN ITALY

renews a tradition of tuna processing that has continued for over 60 years.

Since 2008 we have brought the production to Italy, to Olbia, focusing on a long tradition and art in the processing of tuna.

In 2010 we inaugurated a new plant, with an investment entirely supported by the company of 25 million euros. It is the most modern in Europe and has opened its doors to a new generation of artisans of taste.

and we process it in the same facility.

When we receive whole tuna in our factory, we carry out all stages of production here, from cutting to packaging, following an all-Italian art of cooking, cleaning and selecting fish.

we do not throw away any of our fish.

The focus on sustainability, a continuously optimized cycle to make the best use of the raw material and the introduction of an internal plant for the production of fishmeal for animal husbandry, allow us to process our tuna every day without producing any waste. processing

which contributes to the local economy.

The choice to locate the production in Olbia is a choice against the trend.

We contribute to supporting employment in Italy, offering a concrete boost to the virtuous circle made up of more jobs, more purchasing power, more consumption and therefore more new jobs.

Very high levels of energy efficiency and environmental performance.

100% RENEWABLE ENERGY

The Olbia plant used 100% renewable energy supplied by the Romagna Energia consortium.

LOWER ENERGY CONSUMPTION

In 2020 new interventions were carried out to reduce energy consumption: high-performance cold rooms, new pressurized group for water, new electrical substation, efficiency improvement of boilers for purging.

100% RECYCLING

Plastic, Steel, Wood, Paper and Cardboard all given 100% for recycling.

WATER REUSE

The Olbia plant reused about 30% of the water withdrawn. Investments in new plants to reduce water consumption, continued in 2020.

ENVIRONMENTAL IMPACT

Over 543,000 € expenses and investments to minimize environmental impacts.

NO CLAIM

In the last three years, no formal or litigation claims for environmental impacts of the plant or significant financial penalties received for non-compliance with environmental laws and regulations.

Zona industriale settore 6,

Via Corea 15/17,

07026 Olbia (SS)

+39 0789 550601